Current status

Progress in 2025

- In March 2025 Viridor consulted with the community on plans to deliver a full-scale carbon capture project at Runcorn Energy Recovery Facility (ERF), with a view to submitting a planning application later in the year.

- Viridor completed the Front End Engineering Design (FEED) study for the project in summer 2025 but decided not to proceed with the submission of a planning application.

- Through the remainder of 2025, Viridor undertook a review of the Runcorn CCS project taking lessons from the completed FEED study, together with feedback and learnings from community consultations and the successful permit application.

- The outcome of the review is that the intention is now to split the delivery of carbon capture at the site into two distinct phases.

Plans for 2026

- Work is now focused on the development of the first phase, which will capture CO2 from flue gases from two of the processing lines at our Runcorn facility. The second phase, which will capture flue gases from the remaining two processing lines will be developed at a later date.

- Further engineering design studies are currently ongoing and with a view to preparing an updated planning application for the new concept during 2026.

- The changes to concept will mean further consultation with the community, to be undertaken in advance of the submission of any planning application.

Other planning matters

- Viridor has applied for planning permission to carry out preparatory works for the capture project, including the demolition and replacement of existing buildings on the site and the construction of a temporary car park. It is anticipated that a decision will be made on these applications early in 2026.

- A separate planning application for the Runcorn carbon capture and storage spur that will link to the carbon capture facility at Runcorn, was submitted in July 2025 and continues to progress through the application process. This application was submitted by ENI.

Who is Viridor?

Viridor is a leading resource recovery and recycling business that transforms non-recycled waste into energy.

We’ve invested over £1.2 billion in developing a network of advanced Energy Recovery Facilities (ERFs) across the UK and we deliver innovative ways to reduce, reuse, recycle or recover energy from the things that you sort into your bins every day. We’re an active recycler ourselves, and work with our local authority customers to meet recycling and waste management targets. You can take a tour of our virtual ERF here.

Watch our webinar

We held a webinar on our proposals for carbon capture at Runcorn on Tuesday 18 March.

During 2023/24, Viridor contributed nearly £1 million to the Halton Borough Council Environment Fund which supports community-focused projects in the local area. Recently, this has included a £650,000 donation to fund a new community café in Pickerings Pasture.

Local organisations have also benefited from Viridor’s We Share Community Fund, which is our corporate fund run by our people who choose to support well deserving causes in areas surrounding our ERFs. In Runcorn, these include donations to Halton Haven Hospice and Weston Point Scout Group. We are also ongoing sponsors of Runcorn FC.

Story so far

Viridor has been operating an ERF at Runcorn since 2014, and now treats approximately 1 million tonnes of non-recycled waste each year, generating enough energy to power the equivalent of 211,000 homes.

In May 2021, we announced our five-step action plan to achieve net zero emissions by 2040. Capturing the carbon produced by facilities such as our Runcorn ERF is a key part of this ambition. You can read more about our ambitions for carbon capture at Runcorn here.

Background

Viridor is progressing the UK’s largest opportunity to decarbonise the waste sector, through the use of carbon capture at its Runcorn ERF facility, with CO2 being captured and safely transported through the HyNet pipeline and then stored permanently, deep underneath Liverpool Bay.

Viridor Runcorn would capture around 900,000 tonnes of CO2 each year. It will also see us create net zero power and heat from our facility, helping to decarbonise industry in the North West and contributing to the government’s target of reaching net zero by 2050.

HyNet

The HyNet pipeline is a nationally significant infrastructure project that plans to take captured carbon dioxide from across our region and store it under the sea in Liverpool Bay. Our proposals for carbon capture at Runcorn would connect to the Runcorn Spur Pipeline and wider HyNet network, which is being developed by Eni.

You can find out more by visiting the HyNet website, here.

Why do we need carbon capture?

Human activity has been the main driver of climate change since the 1800s. The production of greenhouse gases (including CO2) is the key reason why the earth is warming faster than ever before, and extreme weather events are becoming more common.

Waste is a major contributor to greenhouse gas emissions and even with improvements in recycling, the average person still throws away around 500kg of non-recycled waste each year. This is the weight of a small car!

However, our industry is well suited to capturing CO2 and it could have a big impact. For example, in Runcorn alone each year, we will capture carbon equivalent to the emissions from 3000 commercial flights between London and New York!

This project will make our site climate positive by producing negative emissions. This is where the total carbon we capture is more than the total fossil (man-made) carbon we produce. We will be capturing natural carbon so we’ll actually be removing carbon from the atmosphere and in doing so we’ll be helping this region to be at the forefront of efforts to reduce the UK’s carbon emissions and reach net zero targets. You can find out more about negative emissions from the Coalition for Negative Emissions, here.

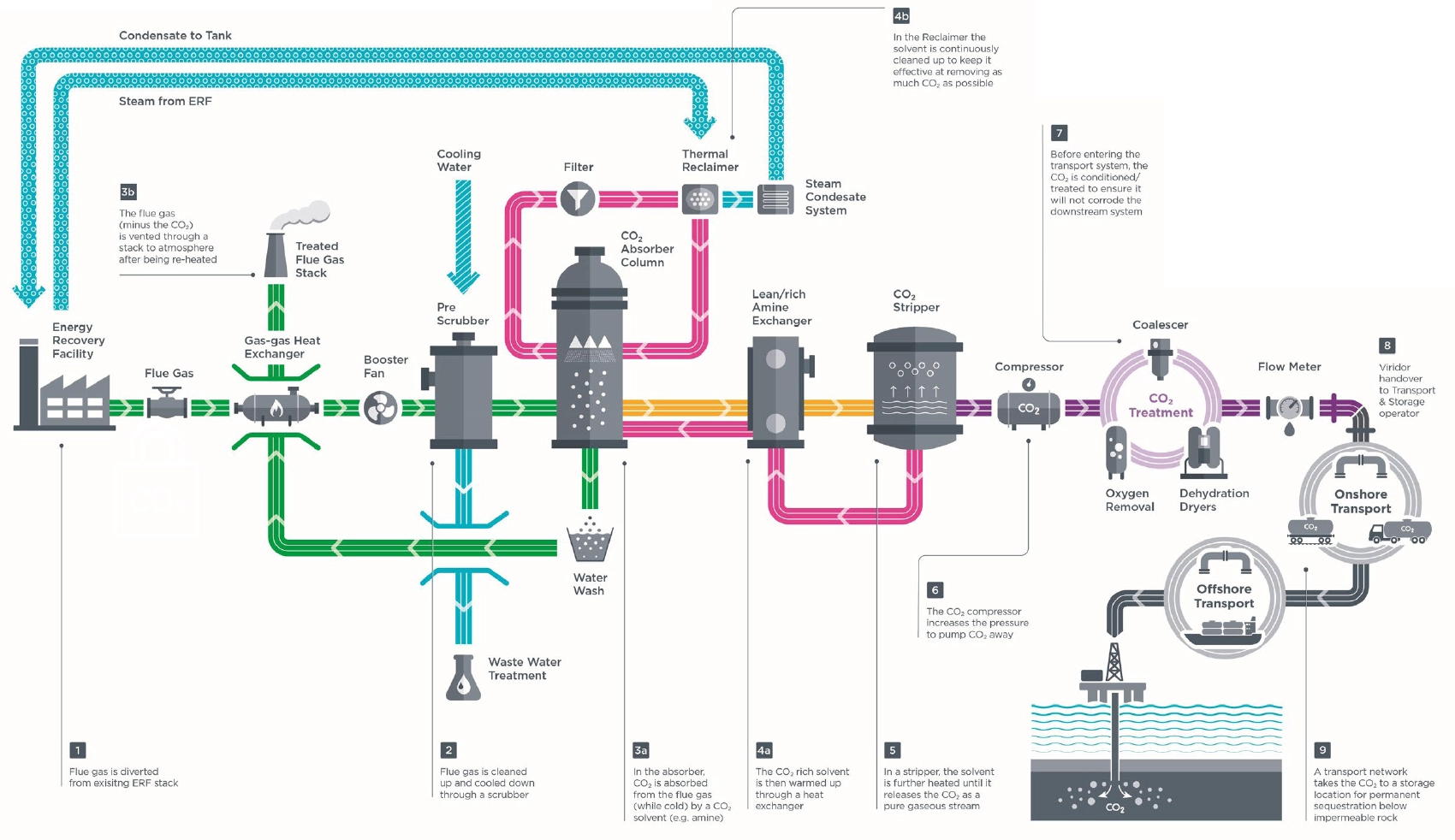

How does carbon capture work?

- Flue gas is diverted from the existing ERF stack into the proposed carbon capture infrastructure.

- The flue gas is then passed through a piece of machinery called a scrubber which cleans it and cools it down.

- The gas then moves to the absorber column, where the CO2 is absorbed from the flue gas (while cold) by a CO2 solvent (e.g. amine). The flue gas (minus the CO2) is vented through a stack into the atmosphere after being re-heated.

- The CO2 rich solvent is then warmed up through a heat exchanger. A reclaimer is also used to continuously clean the solvent to keep it effective at removing as much CO2 as possible.

- In a stripper, the solvent is further heated until it releases the CO2 as a pure gaseous stream.

- The CO2 is then passed into a compressor, which increases the pressure to pump it away from site. Before entering the transport system, the CO2 is conditioned / treated to ensure it will not corrode the downstream system.

- The CO2 captured at Viridor Runcorn is then handed over to the transport and storage operator as part of the HyNet Network, which would take the CO2 for permanent sequestration below impermeable rock.